In a high-performance environment—whether it’s a dealership service bay, an aviation hangar, or a race team’s pit garage—every second counts. When technicians have to dig through cluttered drawers, chase down missing sockets, or waste time figuring out if they have the right tools, productivity drops, and frustration builds. That’s where custom kitting comes in—and it’s one of Sonic Tools’ most powerful solutions for solving real problems on the job.

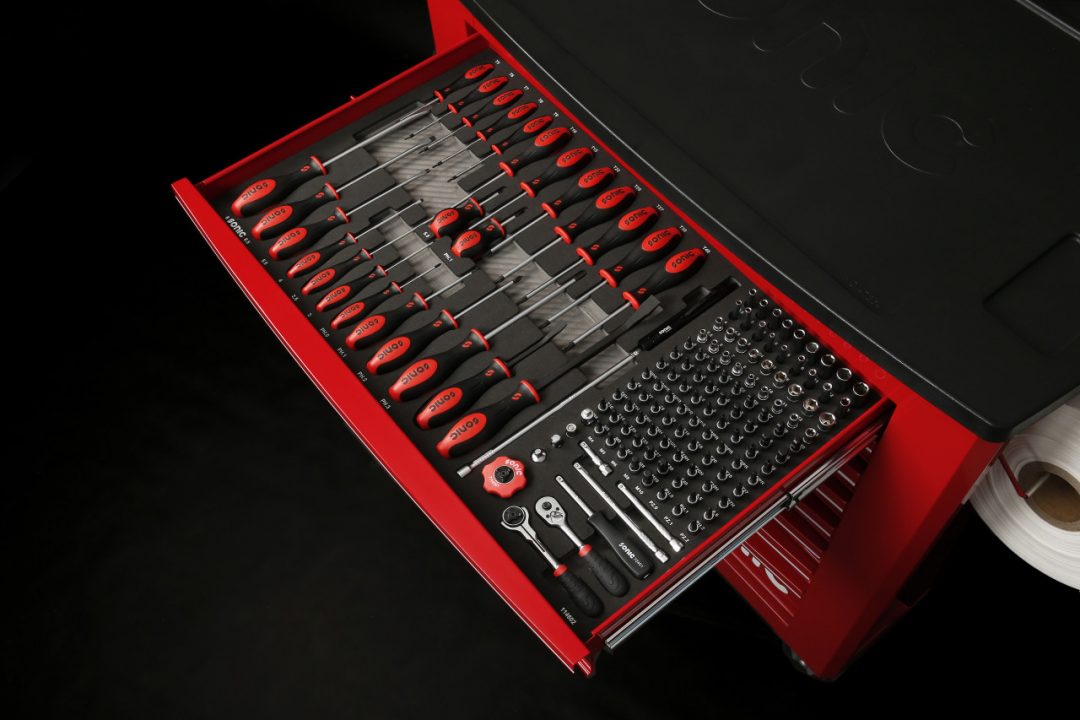

Custom kitting is the process of creating tailored toolsets that are purpose-built for specific roles, industries, or workflows. Instead of using a pre-configured toolset, Sonic works directly with customers to design toolkits that meet exact job requirements—and that fit perfectly into our premium-grade storage solutions with our signature laser-cut foam.

Whether you’re a fleet manager looking to standardize technician tools across multiple locations or a pit crew needing a compact, travel-ready set of essentials, custom kitting ensures your team has what they need—and only what they need—at their fingertips.

Real-World Challenges, Solved

At Sonic, we’ve partnered with companies and organizations across multiple industries, and we’ve seen firsthand how custom kitting transforms work environments. Here are a few real-world problems we’ve solved:

1. Reducing Downtime Due to Missing Tools

In industries like aviation and manufacturing, a missing tool isn’t just inconvenient—it’s a safety concern. Our custom kits come with laser-cut foam that shows a clear visual inventory of each item. It’s easy to see when something is out of place, so techs can act fast. This approach doesn’t just boost accountability—it drastically reduces downtime.

2. Standardizing Equipment Across Locations

Large operations often struggle with consistency. One site may have different tools, brands, and setups than another, leading to confusion, training headaches, and inconsistent service quality. With custom kitting, Sonic helps companies create standardized solutions that can be deployed across all teams—simplifying training, budgeting, and inventory management.

3. Speeding Up Onboarding

New hires often spend the first few weeks learning what tools they need, how to organize them, and what’s missing. Custom kitting eliminates this friction. Each tech receives a ready-to-go system that’s organized, complete, and designed for their role. The result? Faster ramp-up times and fewer mistakes.

4. Meeting Industry-Specific Requirements

Some jobs require unique tools or configurations that standard toolsets simply don’t offer. Our custom kits can be tailored for aviation, EV repair, motorsports, manufacturing, and more—ensuring compliance with regulations and improving technician efficiency.

Built Around You

The custom kitting process at Sonic is more than just swapping out a few wrenches. It’s a collaborative partnership that starts with understanding your needs:

- Consultation & Planning – We meet with your team to understand workflows and operational pain points.

- Tool Selection – Based on your input, we select tools to create a top-tier toolset, from screwdrivers to torque wrenches to specialty tools.

- Foam & Storage Design – We design custom foam inlays that perfectly fit your tool selection, and build them into our toolboxes, carts, or premium cabinetry.

- Delivery & Implementation – Your kits arrive organized and ready to go—no sorting or setup needed.

This level of customization means that every square inch of your tool storage is optimized. No wasted space. No unused tools. Just clean, efficient, job-ready systems.

The Bottom Line: Efficiency Meets Professionalism

Custom kitting isn’t just about having cool foam or a neat setup—it’s about building a work environment where technicians are empowered to work faster, smarter, and with more pride in their space. It boosts morale, minimizes tool loss, and increases the consistency of service across the board.

If you’re tired of mismatched drawers, inefficient workflows, or incomplete sets, it’s time to explore a smarter, more intentional way to outfit your team.

Ready to build your custom solution?

Contact our team today and discover how Sonic’s custom kitting can transform your operation from the inside out.