When it comes to the aviation maintenance industry, the stakes are high. One of the biggest threats to aircraft safety and operational efficiency is Foreign Object Debris (FOD), which can range from a small, misplaced tool to a loose bolt on the tarmac. These seemingly minor instances can cause major damage, leading to costly repairs and even safety hazards. FOD prevention isn’t just important—it’s essential.

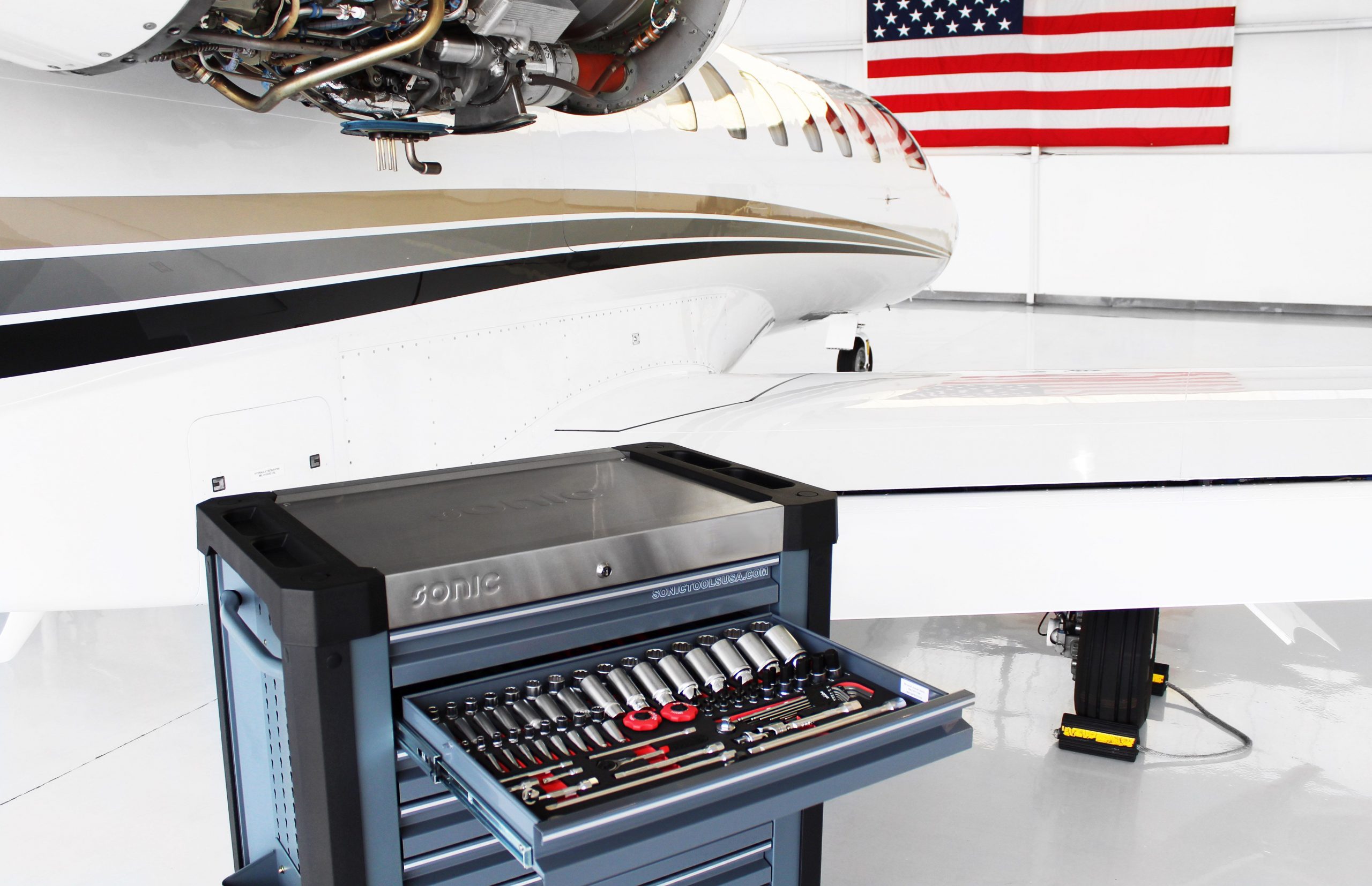

That’s where Sonic Tools steps in. We’re not just providing tools; we’re delivering a system designed to mitigate FOD risks, streamline asset management, and boost productivity across the aviation maintenance industry. Our Sonic Foam System, combined with our serialized tools, offers an advanced solution to these common challenges, helping both aviation technicians and the businesses they serve operate more effectively.

Eliminating FOD Risks with Precision Tool Control

For aviation technicians, precision and efficiency are critical. Every tool must be accounted for, not only for the sake of the task at hand but also to ensure nothing is left behind that could become hazardous. The Sonic Foam System ensures that every tool has a specific place, reducing the risk of misplacement or loss. Technicians can easily identify when something is missing or out of place thanks to the custom foam inlays Sonic provides. This visual organization doesn’t just improve workflow; it actively prevents a small error from becoming a major FOD issue. Additionally, the serialization of each tool allows for full traceability, ensuring that every tool is accounted for at the end of the day.

Enhancing Asset Management with these Solutions

Technicians are often under pressure to deliver fast, accurate maintenance with minimal downtime. Managing tools and equipment is an essential part of their daily tasks. With Sonic’s inventory control solutions and serialized tools, keeping track of assets becomes significantly easier. For MRO Managers or Maintenance Directors, the ability to trace tools through serialization and see exactly where everything is at any given time ensures better asset management and accountability for their team. This level of control also supports compliance, audits, and overall tool management, reducing the operational burden on both technicians and their supervisors.

Every minute counts in aviation maintenance, and the more efficiently technicians can access the tools they need, the faster they can complete the job—without cutting corners. The Sonic Foam System, paired with our inventory control sheets and laser-etched tools, creates an organized environment where technicians spend less time searching for tools and more time focusing on critical tasks. This proven, streamlined process leads up to a 20% increase in productivity. For aviation operations leaders, this means a more efficient workforce without compromising safety or precision.

Empowering Technicians and Their Teams

Sonic’s solutions are built for the technician. These professionals rely on tools that are not only reliable and of high quality, but also designed to make their jobs easier, safer, and more productive. Sonic’s tool solutions don’t just solve organizational problems—they prevent them, giving technicians confidence in their workflow and allowing them to perform at their best.

For the technician’s supervisors, the investment in Sonic is an investment in their teams. Our solutions help create a safer, more efficient work environment that ultimately enhances the performance of the entire operation. With Sonic, you’re providing your technicians with the tools and systems they need to excel, while setting a new standard for safety, productivity, and success in aviation.